The Impact of Robotics on Manufacturing Efficiency

Robotic technology has evolved rapidly in recent years, showcasing impressive capabilities and functionalities. One key advancement is the development of more sophisticated sensors and cameras, enabling robots to perceive and interact with their environment more accurately. This enhancement in perception technology has significantly improved the precision and efficiency of robotic systems in various applications.

Another notable advancement in robotic technology is the integration of artificial intelligence (AI) algorithms, allowing robots to learn and adapt to changing conditions autonomously. By leveraging AI, robots can make real-time decisions and optimize their performance without constant human intervention. This capability has revolutionized industries like manufacturing, where robots now have the intelligence to handle complex tasks with speed and accuracy.

Integration of Robotics in Manufacturing Processes

Robotics has significantly transformed the landscape of manufacturing processes in recent years. With the integration of robotics, industries have witnessed improved efficiency and precision in their production lines. Tasks that were once time-consuming and labor-intensive are now handled swiftly and accurately by robotic systems, leading to higher productivity levels. This seamless incorporation of robotics into manufacturing processes has not only streamlined operations but has also reduced the margin of error, ensuring a consistent and high-quality output.

The adoption of robotic technology in manufacturing has also contributed to enhanced safety standards for workers. By automating hazardous tasks and operating in potentially dangerous environments, robots have helped minimize the risk of workplace accidents. Furthermore, the integration of robotics has enabled manufacturers to reallocate human resources to more complex and value-driven activities, promoting a more dynamic and fulfilling work environment. Overall, the inclusion of robotics in manufacturing processes has paved the way for smoother operations, improved product quality, and a safer workplace for all involved.

• Increased efficiency and precision in production lines

• Reduction in time-consuming and labor-intensive tasks

• Higher productivity levels achieved with robotic systems

• Minimized margin of error leading to consistent high-quality output

The integration of robotics in manufacturing processes has not only revolutionized the way industries operate but has also brought about significant improvements in safety standards for workers. By automating hazardous tasks and operating in potentially dangerous environments, robots have played a key role in reducing workplace accidents. Additionally, the adoption of robotic technology has allowed manufacturers to reallocate human resources to more complex and value-driven activities, creating a more dynamic and fulfilling work environment for employees. With these advancements, the inclusion of robotics continues to drive smoother operations, improved product quality, and overall workplace safety for all involved.

• Enhanced safety standards through automation of hazardous tasks

• Reallocation of human resources to more complex activities

• Creation of a dynamic and fulfilling work environment

• Continued drive towards smoother operations, improved product quality, and enhanced workplace safety

Benefits of Robotic Automation in Manufacturing

Robotic automation in manufacturing brings numerous advantages to businesses across various industries. Firstly, it significantly boosts efficiency by streamlining production processes and reducing human error. Robots can work around the clock without breaks, leading to increased productivity and faster turnaround times for manufacturing tasks.

Secondly, the implementation of robotic automation in manufacturing enhances workplace safety by removing humans from hazardous environments and repetitive tasks. This helps in reducing the number of workplace accidents and injuries, contributing to a healthier and more secure work environment. Furthermore, robots can handle heavy lifting and dangerous materials with ease, further safeguarding workers from potential harm.

What are some of the advancements in robotic technology that have revolutionized manufacturing?

Advancements such as artificial intelligence, machine learning, and sensor technology have greatly improved the capabilities of robots in manufacturing.

How are robotics integrated into manufacturing processes?

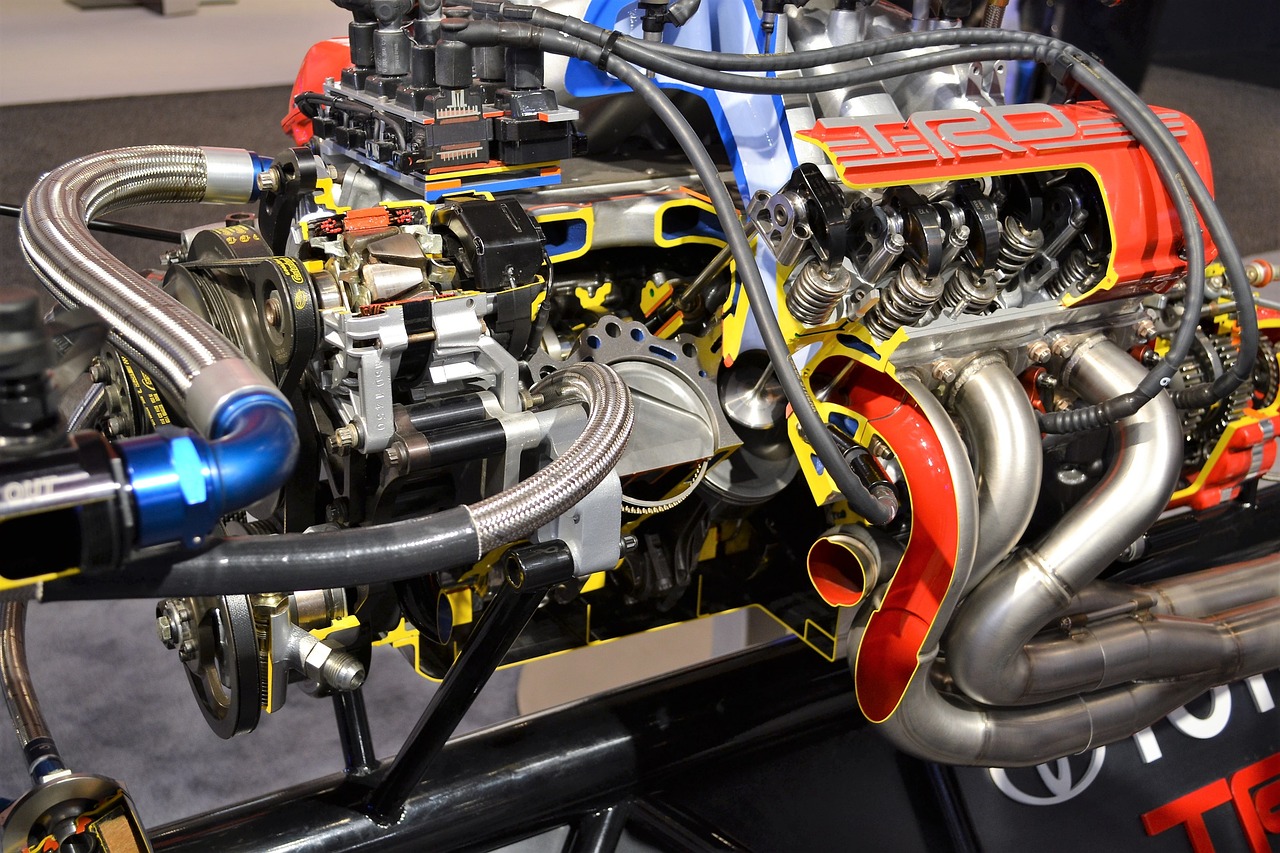

Robotics are integrated into manufacturing processes through the use of robotic arms, automated guided vehicles, and other robotic systems that can perform tasks such as welding, painting, and assembly.

What are some of the benefits of robotic automation in manufacturing?

Some benefits include increased productivity, improved quality control, reduced labor costs, enhanced workplace safety, and greater operational efficiency.

Can robotic automation help in reducing downtime in manufacturing plants?

Yes, robotic automation can help reduce downtime by working around the clock without the need for breaks, resulting in continuous production and minimal interruptions.

How can companies justify the investment in robotic automation for their manufacturing processes?

Companies can justify the investment in robotic automation by considering the long-term cost savings, increased output, improved product quality, and the competitive edge it provides in the market.